News

Contact Us

Suzhou Kaifa New Material Technology Co., Ltd.

Email:heqing@szkfxc.com

Email:sales@szbknm.com

Email:bkxc.bonnie@gmail.com

location:Home » News » Material properties

Alumina tube products

edit:Kaifa Popularity:5902 Time:2020/1/12

The melting point of oxide ceramics is mostly above 2000 ° C, and the firing temperature is about 1800 ° C; its strength decreases with increasing temperature, and pure oxide ceramics will not oxidize at any high temperature.

Of course, alumina-based products also include alumina insulation tiles, alumina insulation bases, alumina insulation gaskets, and so on. We make the following introduction to the characteristics of our company‘s alumina tube products:

1. Alumina insulation tile

material: alumina

structure: ionic crystal

Temperature range: 0 ~ 1500 ℃

Application places: ingot furnace, polycrystalline furnace

characteristics: resistance Corrosion, high temperature resistant

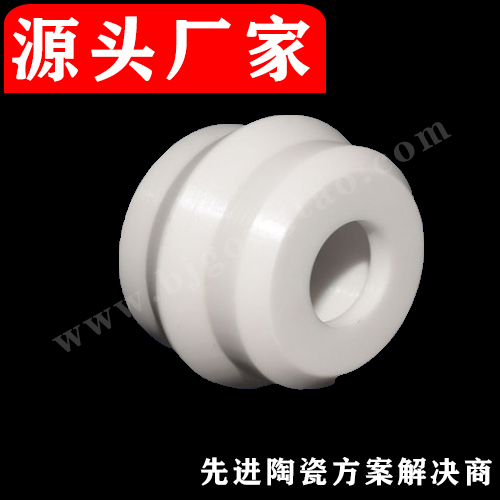

alumina insulation tile picture:

Material: Alumina

structure: Ion crystal

Temperature range: 0 ~ 1200 ° C

Applicable places: Polysilicon, single crystal silicon ingot furnace

Features: heat resistance, corrosion resistance, good insulation performance

Picture of alumina insulation tile:

material Quality: Al2O3-99%

Structure: Ion crystal

Temperature resistance range: 0 ~ 1200 ° C

Applicable places: Single crystal furnace The

main specifications are: (all flat mouth sealed, lid or bottom can be made with sealed card slot, machine pressure Molding)

320 * 230 * 65 , 320 * 230 * 50, 296 * 296 * 100, 325 * 235 * 100, 100 * 100 * 30, 100 * 100 * 25 and other specifications, and equipped with 320 * 230 * 15 belt Card slot cover zinc oxide pressure-sensitive industry can be used for more than 1 year if it is not more than 1280 degrees, double the life of corundum mullite products, and 100 * 100 * 30 or 100 * 100 * 25 double-sided flattening box bowl The life span is several times that of 99 porcelain products, and the price is lower.

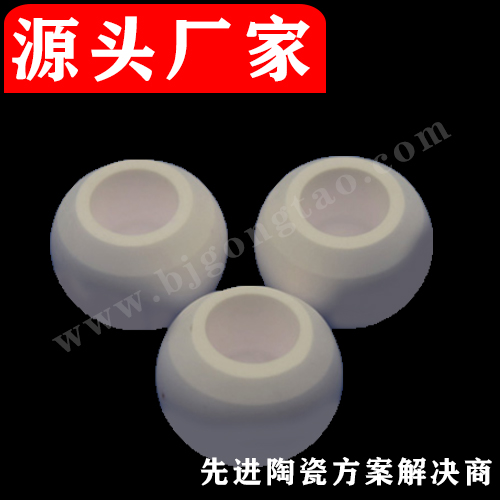

Picture of alumina insulated base:

Material: Alumina

structure: Ionic crystal

Temperature range: 0 ~ 1200 ° C

Applicable places: Polycrystalline silicon, single crystal silicon ingot furnace

Features: AL2O3: 98-99.5%;

Density: 3.85;

Working temperature: 1750 ℃;

flatness:

> 250mm: ± 0.1mm;

<250mm: ± 0.02mm;

maximum size range: length 1000mm

Main specifications: D90 * D57 * 5mm, D100 * D62 * 6mm, D100 * D57 * 6mm

Application range: oxidation Aluminum ceramic wear-resistant, pressure-resistant, insulation, high-temperature resistant sintering equipment and machinery accessories equipment;

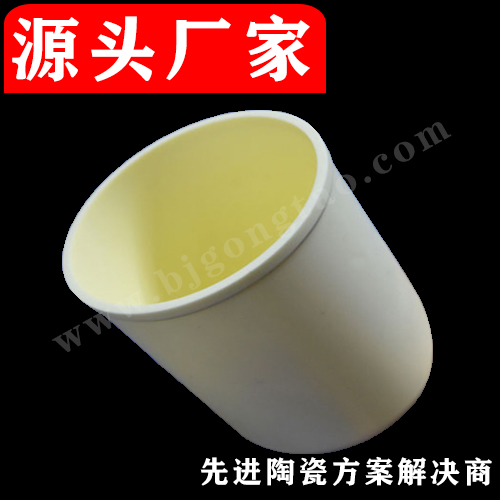

Picture of alumina insulation gasket:

Next:

You really under...

Previous:

Thermocouple alu...