Suzhou Kaifa New Material Technology Co., Ltd.

Email:heqing@szkfxc.com

Email:sales@szbknm.com

Email:bkxc.bonnie@gmail.com

Mullite ceramics

Ceramic material: Mullite ceramic

Processing accuracy: ± 0.001mm

Product features:

Provide color:

Custom processing: can provide drawings and sample processing customization

Email:heqing@szkfxc.com

Email:heqing@szkfxc.com

Mechanical properties

The mechanical properties of the high-purity mullite ceramic sintered body are determined by the ratio of Al2O3 / SiO2 and the microstructure, especially the mullite ceramic with Al2O3 content of 68%, the bending strength reaches 570MPa at 1300 ℃, and the fracture toughness Kic 5.7MPa.Nm, which is 1.6 times higher than that at normal temperature. This kind of strength and toughness not only does not decay but increases greatly with the increase of temperature. It is unique among existing high-temperature ceramic materials except SiC, which is also high Pure mullite ceramics have excellent properties as high-temperature materials.

Optical performance

Although the mullite crystal is not a cubic crystal system, it is only an orthorhombic crystal system, but due to the small birefringence of light (only 0.012), ceramic materials with certain transparency can be obtained under certain conditions. High-purity ultrafine powder prepared by alkoxide hydrolysis method can be obtained by transparent mullite porcelain sintering at 1750 ℃ under vacuum.

The main application fields of high-purity mullite ceramics:

Refractories

Mullite ceramics have the characteristics of high melting point, creep resistance, low expansion coefficient, excellent thermal shock resistance and corrosion resistance. Mullite refractory bricks can be used as linings for various high-temperature kilns, including furnace kilns and blast furnaces. , Lining materials such as hot iron pouring trough and continuous casting furnace. Orimoto has used Dilaishi refractory material to line the lower part of the rotary valve outlet that controls the flow of molten steel. It is said that the silicon in mullite contains 10-40% mullite, which greatly improves the thermal shock resistance. In addition, it is also widely used in the lining of cement high temperature calcination area.

High temperature engineering materials

When the United States developed advanced ceramic engines with low thermal expansion and low heat loss in the early 1990s, mullite was listed as the main candidate material. The mullite ceramic cylinder head base plate developed in China has been successfully tested on a desert vehicle, which initially shows a good application prospect for this material. The mullite composite material toughened by aluminosilicate long fiber in Germany has been successfully tested and used on the exhaust device of propeller aircraft; Japan has used mullite ceramic material to make a conveyor belt to replace the stainless steel conveyor belt in the tunnel kiln. Mullite ceramics are also widely used in heat-resistant materials such as metal melting crucibles, high-temperature protection tubes and thermocouple protection tubes, which prove that their corrosion resistance to high-temperature gases is better than alumina ceramics, and they have good air tightness. As high-temperature engineering materials, Especially suitable for making high temperature protection tube.

Electronic packaging materials

The key to high-tech modern microelectronics is to solve the technical materials of microelectronic packaging. Computer systems are increasingly demanding high-performance packaging, and ceramic substrates are facing new demands. The dielectric constant of ceramic materials for high-performance packaging is required to be very low. When the package size is large, the higher the density, the higher the requirement for ceramic materials, and the low dielectric constant can cause rapid signal transmission. The signal transmission time of pure mullite material is about 14% lower than that of Al ceramic substrate. If mullite-glass and cordierite composite materials are used, the transmission time will be further reduced. This kind of mullite-glass composite material is used in the supercomputer developed by Hitachi, Japan. In the AIN (aluminum nitride) substrate Lai stone ceramic materials have been successfully used as packaging materials for its cover.

Optical materials

Mullite has higher light absorption performance than spinel, sapphire and other materials. Among the window materials used in harsh chemical conditions and withstand high-temperature mechanical applications, mullite is an excellent infrared-transmitting material.

Warm tips: Kaifa products are only used for scientific research, not for human body,different batches of products have different specifications and performance.The website pictures are from the Internet. The pictures are for reference only. Please take the real object as the standard. In case of infringement, please contact us to delete them immediately.

Quality AssuranceHigh standards of the industry-leading

|

Ceramic tube Thermocouple protection tube |

|

Ceramic rod Ceramic shaft sleeve insulated |

|

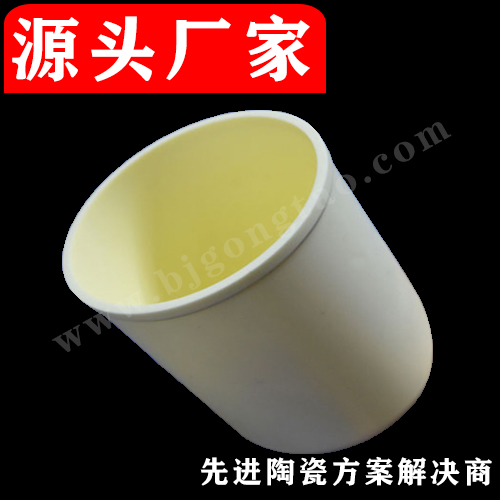

Ceramic crucible High quality and high temperature resistant |

|

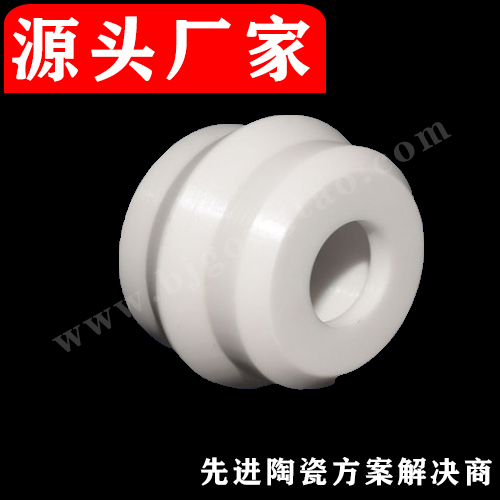

T-shaped concave convex tube High temperature insulator porcelain mouth porcelain |

|

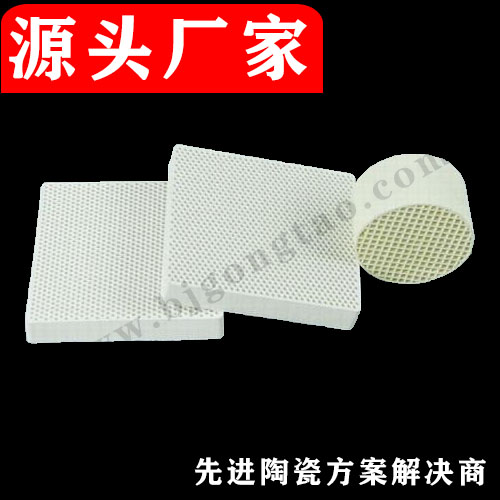

Ceramic plate Alumina plate, ceramic plate, bearing plate, |

|

Ceramic gasket High temperature resistant ceramic ring, |

|

Screw nut Insulating screws, corrosion-resistant bolts, |

|

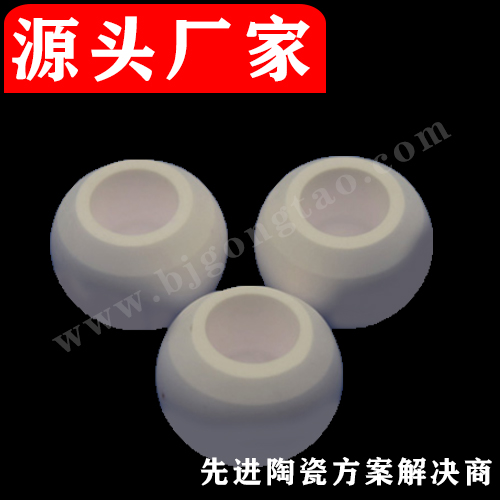

Ceramic ball Alumina and zirconia ultrafine grinding media. |